TL;DR: Your 30-second overview

We know you’re busy. Here are the key takeaways:

- Knowledge management in manufacturing is critical for safety, speed, and compliance.

- A modern knowledge management system reduces downtime and prevents costly mistakes.

- This playbook shows how to capture, share, and apply knowledge across manufacturing organizations.

Manufacturing is fast, complex, and unforgiving. You run multiple sites, face strict audits, and deal with high turnover.

Without effective knowledge management, your business risks delays, safety issues, and wasted effort.

We’ve seen what happens when critical knowledge gets stuck in files, is lost with retiring staff, or is trapped in one plant.

The result? Teams repeat mistakes, downtime grows, and opportunities vanish.

The good news is that modern knowledge management makes these problems easier to solve. With the right system, you can capture know-how, share it across locations, and empower every employee to make better decisions.

Why knowledge management matters in manufacturing in 2026

Running a manufacturing business today is tougher than ever. Deadlines are tighter. Rules change fast. Customers expect more.

At the same time, plants face constant churn. Regulations shift. Systems multiply. Experienced staff retire, and new hires arrive with little context.

When knowledge is scattered, the impact shows up fast:

- Operators repeat the same mistakes.

- Downtime grows while teams “reinvent the wheel.”

- Audits become stressful, with critical records missing.

- Valuable lessons walk out the door with retiring staff.

We’ve seen this play out many times. One site struggles with a quality issue that another solved years ago. Or a new hire spends weeks guessing at the right process instead of learning it on day one.

That’s why knowledge management matters. With a robust knowledge management system, your teams reduce downtime, stay compliant, and move new products to market faster.

So what exactly stands in the way of effective knowledge management in manufacturing, and what benefits can you unlock by fixing it?

The 5 biggest knowledge management challenges in manufacturing (and the benefits of solving them)

Every manufacturing organization knows that knowledge can make or break daily operations.

The problem is that most businesses struggle to manage it in a way that drives results. Let’s look at the biggest challenges your teams face, and the benefits of solving them.

1. Tribal knowledge walks out the door

Challenge: Experienced operators retire or leave, taking years of tacit knowledge with them.

Benefit: When you capture and share this specialized knowledge, new employees learn faster, and onboarding is smoother.

Example: A veteran technician knows the “unwritten fix” for a machine fault. Without capturing that, a new hire wastes hours troubleshooting.

2. Knowledge silos across sites create compliance risk

Challenge: In multi-location plants, process knowledge and audit records are often stored differently at each site — scattered across drives, folders, or local systems. This inconsistency makes it hard to compare performance or prepare for audits.

Benefit: A centralized knowledge management system ensures every site works from the same set of procedures and records. This reduces audit stress, improves compliance, and helps teams learn from one another instead of repeating mistakes.

Example: A global manufacturer consolidated all SOPs, training materials, and audit documentation into one knowledge hub. Now, when regulators request proof, every plant can instantly provide the right version of a record, no matter where it originated.

3. Document chaos slows everyone down

Challenge: Critical knowledge assets are buried in folders, emails, or outdated systems. Teams waste time hunting for the right version or duplicating work when they can’t find it.

Benefit: A centralized knowledge management system makes essential information instantly searchable and accessible, freeing teams to focus on production.

Example: At one manufacturer, quality teams struggled with duplicate versions of SOPs across different drives. Without a central hub, operators sometimes followed outdated instructions, leading to errors and rework. By consolidating documents in one system, the company reduced time spent searching and improved compliance at the same time.

4. Knowledge locked in multiple formats is hard to use

Challenge: Manufacturing knowledge rarely comes in one format. SOPs live in PDFs, machine data in logs, designs in CAD files, and improvements in short videos or photos. Without a way to bring these formats together, teams struggle to curate and extract the insights they need.

Benefit: A modern knowledge management system makes multi-format content searchable, comparable, and usable. It doesn’t just store files — it helps teams synthesize insights across formats so past lessons inform future projects.

Example: A process improvement can be explained in a training video and validated in a PDF report. Without a central hub, these pieces stay scattered. With a unified system, engineers see the full picture and apply it directly to the next product launch.

5. Adoption fails if the system adds friction

Challenge: In manufacturing, even the best-intentioned knowledge initiatives stall if employees see them as extra work. When tools are clunky or time-consuming, frontline staff simply stop using them.

Benefit: A knowledge management system that is intuitive and low-effort encourages adoption. By making it easy to capture and find knowledge in the flow of work, you build habits of sharing that support long-term cultural change.

Example: One manufacturer rolled out a legacy tool that required multiple logins and complex uploads. Within months, usage dropped to near zero. By switching to an easy-to-use system with natural-language search, operators and engineers actually used it — and leadership finally saw knowledge sharing stick.

The reality is simple: Every challenge is also an opportunity.

When your business manages knowledge effectively, you reduce downtime, keep compliance on track, speed up product launches, and foster innovation across your plants.

Next, let’s look at the different types of knowledge your teams rely on, and why capturing each one matters.

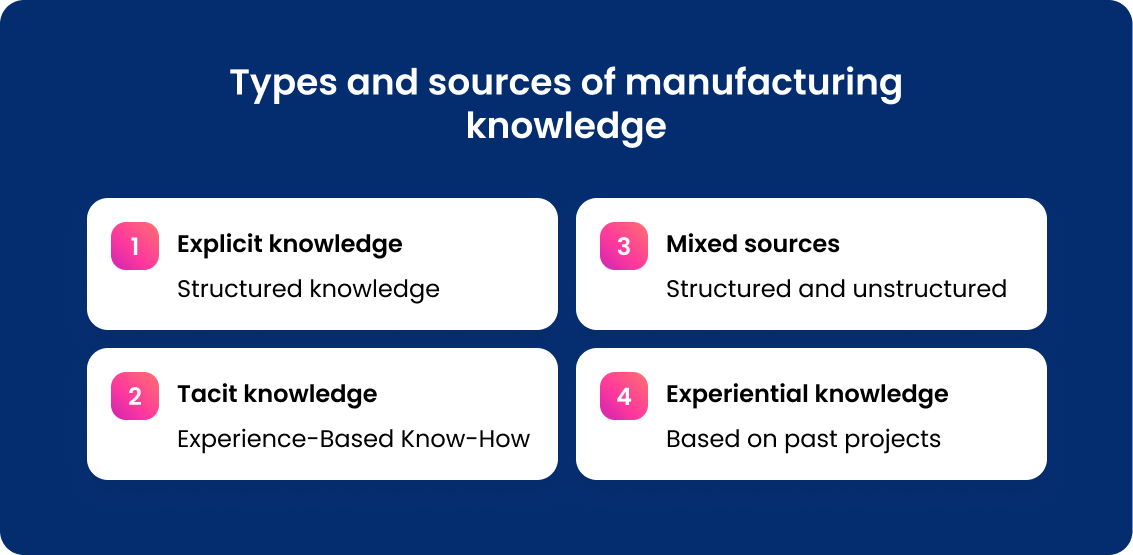

Types and sources of manufacturing knowledge

Not all knowledge in manufacturing looks the same. Some of it is easy to capture in a document. Other parts live in the heads of experienced personnel and can disappear overnight if not shared.

Explicit knowledge

This is structured knowledge you can write down or store in systems. It includes SOPs, work instructions, process flows, and quality documentation. These knowledge assets are essential for audits, training, and standardized processes.

Tacit knowledge

This is the know-how that comes from experience. It includes troubleshooting tips, shortcuts, and insights that operators gain on the floor. When tacit knowledge is not captured, businesses risk repeating mistakes and losing critical knowledge when staff leave.

Structured and unstructured sources

Manufacturing processes create both organized and unorganized information. Structured sources include reports, manuals, or training materials. Unstructured sources include videos, machine data, photos, emails, and production logs. Both types contain valuable content that your business needs to manage.

Experiential knowledge

Lessons learned from past projects are another powerful source. When your teams capture what worked and what failed, you support continuous improvement and foster innovation across sites.

Understanding the different types of knowledge helps you see why a robust knowledge management system must support multiple formats and make it easy for staff to contribute.

Let’s now walk through practical steps your business can take to improve knowledge management in manufacturing.

7 practical steps to improve knowledge management in manufacturing

Improving knowledge management in manufacturing is not about one big project. It is about clear, practical steps your teams can follow.

Here is a playbook you can apply across plants and sites.

Step 1: Map and audit your knowledge landscape

Start by identifying your knowledge assets. Where are they stored? Who owns them? How often are they used?

Pinpoint gaps, duplicates, and risks such as tacit knowledge locked in people’s heads.

It helps to start by learning how to create a knowledge base tailored to your plants.

Stravito supports this step with easy migration tools, automatic tagging, and centralization across legacy systems.

Step 2: Centralize and standardize knowledge for access and reuse

Scattered folders slow down decision-making. Consolidate knowledge into one, user-friendly system.

Standardize naming, tagging, and version control across locations so every site speaks the same language.

A solid knowledge management framework ensures teams follow a structured approach everywhere.

Stravito provides out-of-the-box collections, semantic search, and permissions that balance global and local needs.

Step 3: Capture and share tacit and tribal knowledge

Some of the most critical knowledge never makes it into a manual. Capture it before it disappears.

Encourage operators and engineers to document improvements, troubleshooting steps, and lessons learned using video, voice, or photos.

Stravito makes this easy with mobile upload, multi-format ingestion, and transcription so staff can share knowledge in any format or language.

Step 4: Make knowledge findable and actionable at the point of need

Knowledge only helps if staff can access it at the right moment.

Integrate knowledge into daily workflows, from QR codes on machines to links in maintenance systems.

With AI knowledge management, employees can search in natural language and get rapid access to essential information.

Stravito supports this with AI-powered search, personalized dashboards, and integrations with ERP, MES, and Teams.

Step 5: Embed knowledge management into training, onboarding, and continuous improvement

Give new employees curated collections of SOPs, training materials, and best practices so they get up to speed faster.

Capture feedback and lessons learned after audits, incidents, or past projects to drive continuous improvement.

Stravito enables this with training modules, analytics on content usage, and built-in feedback capture.

Step 6: Monitor, measure, and optimize knowledge usage

You cannot improve what you do not measure. Define clear metrics such as:

- Time spent searching for information

- Number of repeated errors

- Training completion rates

- Audit findings closed

- Employee satisfaction scores

These measures should be part of a broader knowledge management strategy that aligns knowledge with business goals.

Tracking knowledge management KPIs ensures your system delivers results that matter.

Stravito provides dashboards, automated reporting, and content gap analysis so you can identify gaps and improve over time.

Step 7: Foster a culture of knowledge sharing for long-term success

Technology is only part of the solution. A knowledge-sharing culture ensures long-term adoption.

Recognize and reward employees who share knowledge. Show teams the wins, such as fewer line stops, because a troubleshooting guide was shared.

These enterprise knowledge management tips can help you build engagement across plants.

Stravito supports this with engagement analytics, notifications, and internal communications that highlight knowledge contributions.

Improving knowledge management in manufacturing is not only about storing information.

It is about creating systems and habits that help your teams learn faster, share smarter, and make better decisions.

As you consider what steps to take, it is also important to know how to choose the right knowledge management system for your business.

Choosing the right knowledge management system for manufacturing

Manufacturing leaders like you know that the right tool can make the difference between smooth operations and constant delays.

A knowledge management system should fit the realities of your plants, not create extra work. Here is what to look for, and what to avoid.

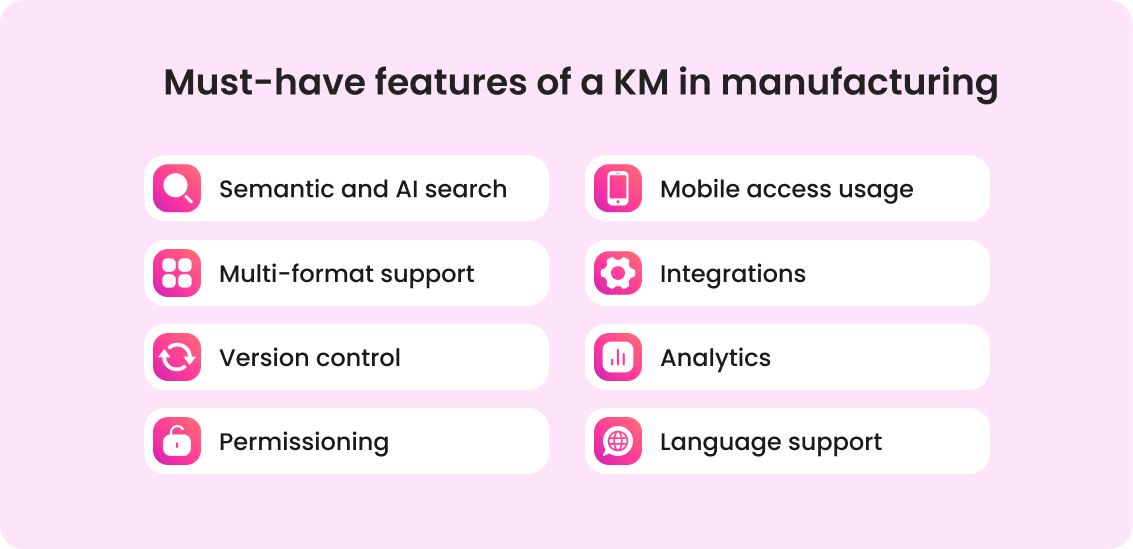

Must-have features of a knowledge management in manufacturing

Your teams need features that support real production environments, not just back-office use. Look for:

- Semantic and AI search so staff can ask questions in natural language. This saves time during line stops when every minute matters.

- Multi-format support for SOPs, videos, CAD files, and images. Manufacturing knowledge is visual, and your teams need more than text.

- Version control to prevent errors from outdated procedures. Running the wrong document can cause compliance issues or failed audits.

- Permissioning so local sites and global teams can both work securely. Plants need autonomy, but headquarters must still protect critical data.

- Mobile access for frontline employees who are rarely at a desk. Operators should find instructions quickly on the floor, not back in the office.

- Integrations with ERP, MES, or collaboration tools like Teams. Knowledge management should fit into daily workflows, not sit off to the side.

- Analytics to measure usage and spot knowledge gaps. This helps identify what content drives results and where you need improvement.

- Language support so teams in multiple regions can access knowledge easily. This reduces errors and builds consistency across locations.

These are the design principles behind Stravito.

The platform emphasizes usability and multi-format support so manufacturing companies can scale knowledge sharing across plants without heavy customization.

What to avoid

Not every system is built for the complexity of manufacturing. Avoid:

- Tools that require large IT projects before you see results.

- Platforms that demand weeks of training before employees can use them.

- Systems that only support documents, ignoring video or process knowledge.

Because Stravito deploys out of the box, it avoids the IT-heavy setup that slows adoption. Its intuitive design reduces training needs, making it simple for engineers and frontline staff to share knowledge.

Choosing the right knowledge management system is not just about features. Your business needs a partner that understands how manufacturing organizations operate and can support both your immediate needs and your long-term growth.

With the foundation in place, it is worth exploring what the future of knowledge management in manufacturing will look like and how emerging technology is shaping it.

Final thoughts: turning knowledge into a manufacturing advantage in 2026

Knowledge is one of your most valuable assets. Managed well, it reduces downtime, strengthens compliance, and helps your teams work smarter across every site.

Managed poorly, it leads to errors, delays, and missed opportunities.

The good news is that knowledge management in manufacturing is no longer a burden. With the right systems and strategies, your business can capture critical knowledge, share it seamlessly, and apply it to drive safer, faster, and more innovative operations.

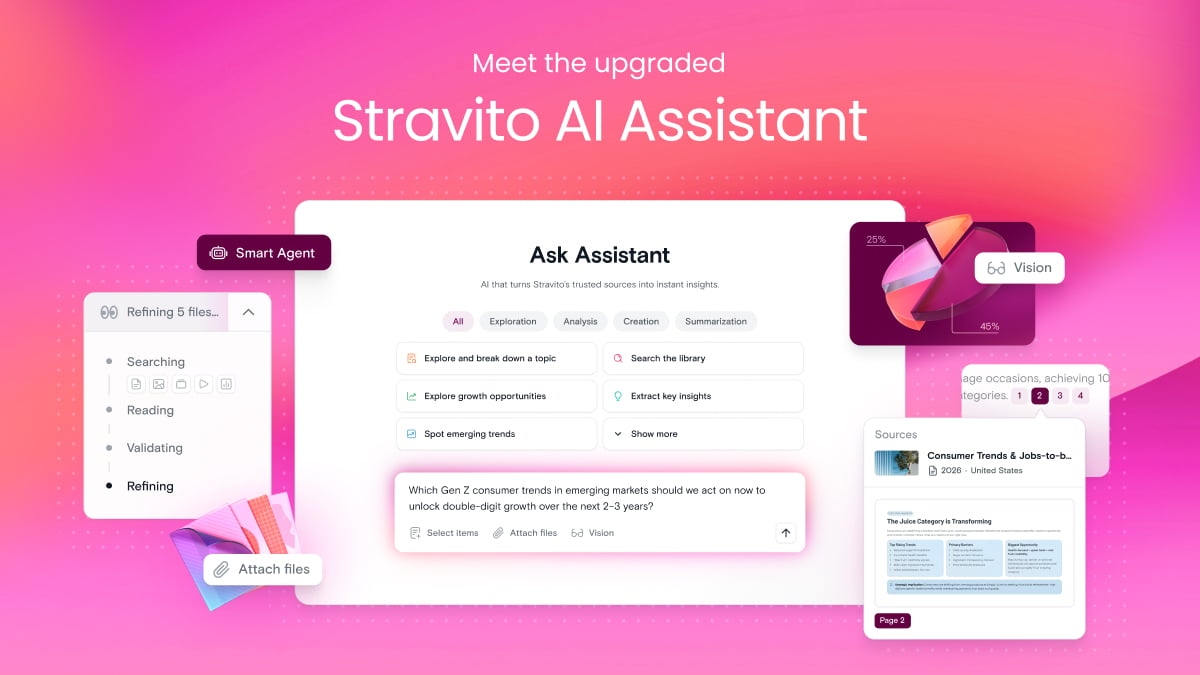

At Stravito, we believe knowledge management should be simple and effective. Our role is to help you build the foundations that let every employee, from new hires to experienced personnel, make better decisions with confidence.

Ready to turn knowledge into a competitive edge for your business? Request a Stravito demo today and see how your teams can put insights to work.

FAQs

What is knowledge management in manufacturing

Knowledge management in manufacturing is the process of capturing, organizing, and sharing knowledge across plants and teams.

It ensures that standard operating procedures, troubleshooting guides, and lessons learned are accessible at the point of need.

This helps reduce downtime, protect compliance, and improve product quality.

Why is knowledge management so important for manufacturers?

Manufacturing processes are complex and highly regulated. Without effective knowledge management, businesses face knowledge loss, duplicated work, and critical errors.

A robust knowledge management system supports risk management, continuous improvement, and overall business performance.

It helps teams make faster decisions and creates a foundation for innovation.

What are best practices for capturing tribal knowledge?

Start by encouraging experienced personnel and subject matter experts to document specialized knowledge.

Use video, voice notes, and photos to capture tacit knowledge from the shop floor.

Store this content in a centralized repository so new employees can easily access it. Over time, this supports training, employee satisfaction, and a stronger culture of knowledge sharing.

How does Stravito support manufacturing knowledge management needs?

Stravito is designed to make managing knowledge simple for manufacturing companies.

The platform supports multi-format content like SOPs, CAD files, and training materials, and provides semantic and AI-powered search for rapid access to essential information.

With features like version control, analytics, and mobile access, Stravito helps businesses integrate knowledge management into daily operations and foster collaboration across multiple locations.

How do you measure success in knowledge management for manufacturing organizations?

Measuring success starts with the right knowledge management KPIs.

Common measures include time spent searching for information, reduction of repeated errors, and training completion rates.

You should also track employee satisfaction, audit readiness, and how knowledge assets contribute to decision making processes.

Data analytics helps identify gaps, highlight valuable content, and show how knowledge creation supports both business goals and continuous improvement.